Tensioned Access Platforms (TAP) – Walk-on nets

A platform net would basically consist of the assembly, anchoring and tensioning of safety nets of no more than 60 mm mesh. Theese nets are manufactured according to the EN-1263.1, and installed means of straps with ratchet and using these as a sort of transversal beams forming net grids. The working height must be equal to or less than 1.5 m underneath the lower edge of the construction.

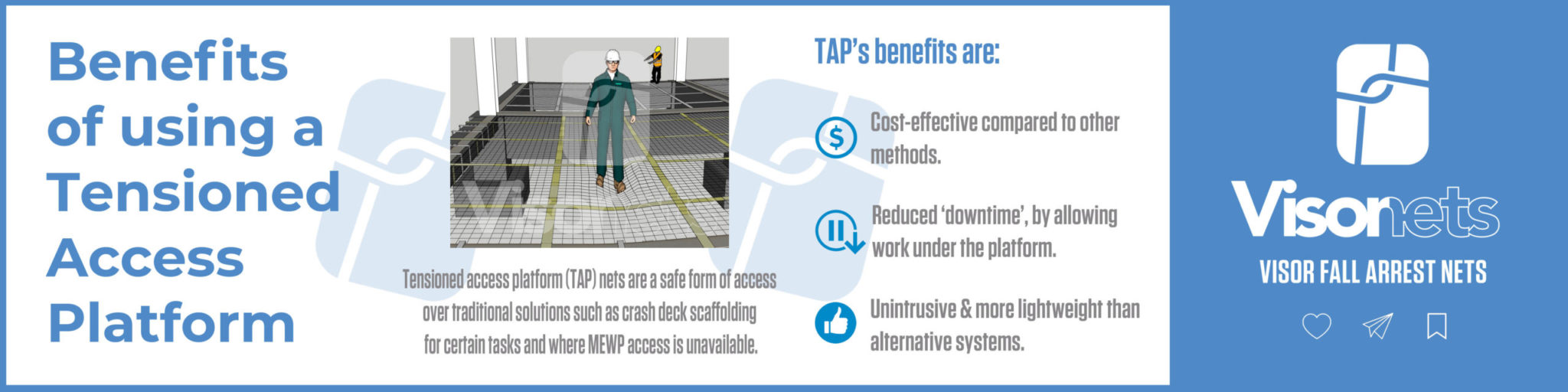

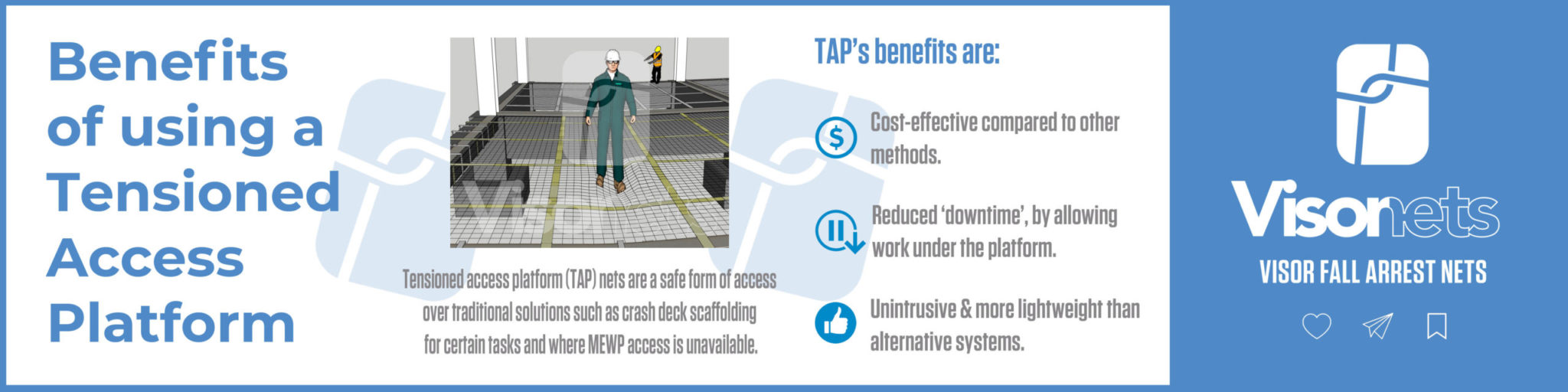

Work Positioning nets benefits

In combination with an adequate system of edge protection, it is a safe system for workers. Moreover, it can be combined with debris meshes and makes it possible to carry out work independently of the activities at lower levels. Being all theese the main reason for the rapid growth of the use of this system internationally.

We can find different benefitious points for installing nets as tensioned access platforms. The first of them are the prize: they are an economical solution for safe works at heights. Secondly, you can install and remove the TAPs nets efficiently. Finally, theese platforms entail minimal disruption to the job site or occupied building.

Tensioned Access Platforms applications

Working platform nets provide a suitable and economic temporary walkable platform developed in lots of works, e.g.

- assembly, exchange, maintenance or inspection tasks of roof elements;

- structural alterations, such as at a super market, where space saving solutions are required;

- optimization of workflow at construction of industrial plants;

- assembly, maintenance or inspection works in construction levels, which are hardly accessible in a conventional way and due to restrictions present on site, like it may occur at large-scale construction projects like stadiums, viaducts…

- below deck structure like wharves, bridges or piers;

- paintings or glazing projects;

- or even in mining works.

It exists a large list of sites which can be benefited by the use of tensioned acces platforms. Shopping malls, train stations, conservatories, church naves, natatoriums, hangers, power stations, water towers, offshore drilling rigs, refineries…

Standard regulations

On the other hand, we must say that there is not yet an international standard. Although the British FASET, have published their own usage guidelines and technical specifications. This document helps to know the main installation conditions, limitations and elements that make up this system.

TAP must design and install by qualified technicians

If you need more information about this product, you can consult us or write an email to [email protected].